High Pressure Roll Briquette Machine

High Pressure Roll Briquette Machine is a kind of briquetting machine,added screw pressure device on the basis of hydraulic ball press, which is used for briquetting materials with little or even zero moisture. Such as various mineral powder, metal powder, pulverized coal, coke powder and other high value-added waste.

Why should we choose High Pressure Roll Briquette Machine?

- 1. The finished product made by the hydraulic roller can maintain the high purity of the material.

High Pressure Roll Briquette Machine is a briquetting machine that can produce briquettes without adhesive. If your material needs high purity, hydraulic roller press is the most suitable choice. In contrast, ordinary roller press usually needs to add 5-20% adhesive. - 2. Materials that cannot be mixed with water.

Some materials, such as quicklime, magnesium oxide, etc. When they are mixed with liquid binders, they will produce chemical reactions and become other materials. The use of hydraulic roller briquetting machine is the best way to make original briquettes. - 3. Make the coal ball have higher density.

With high pressure and stable feeding. The hydraulic roller press will increase the density by 1-3 times.

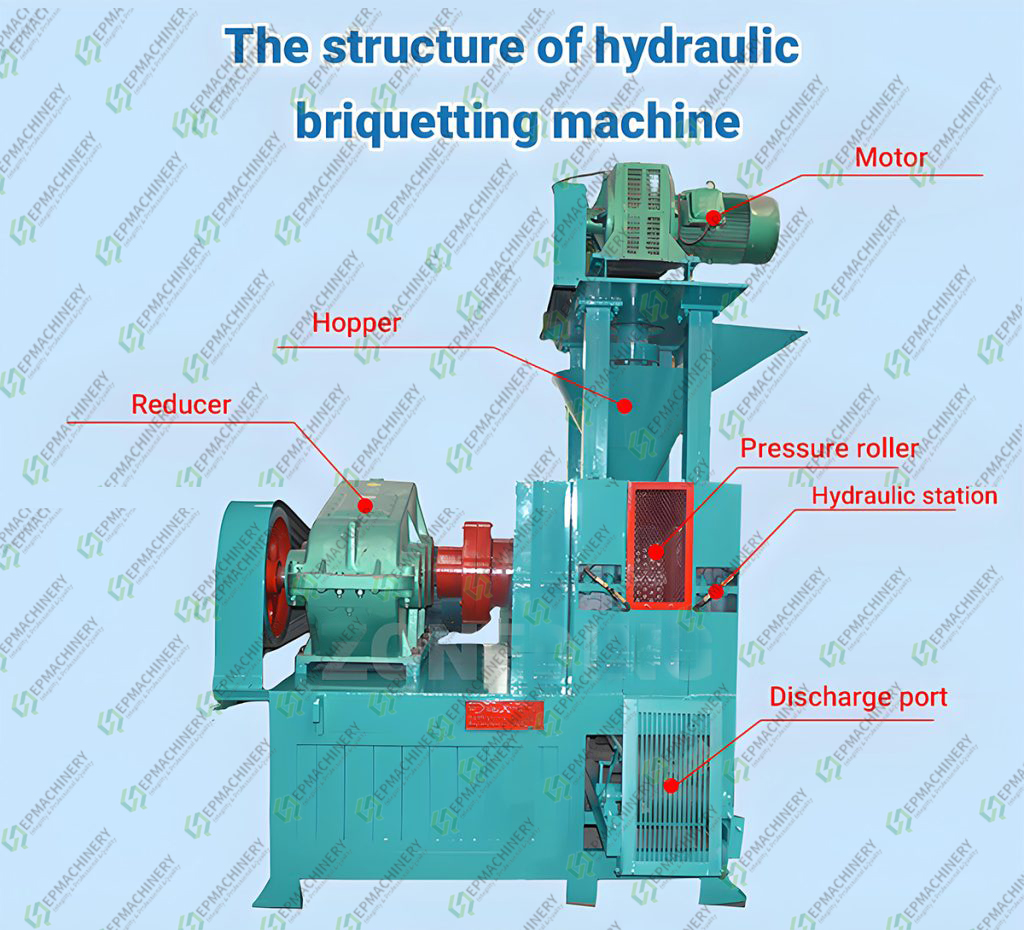

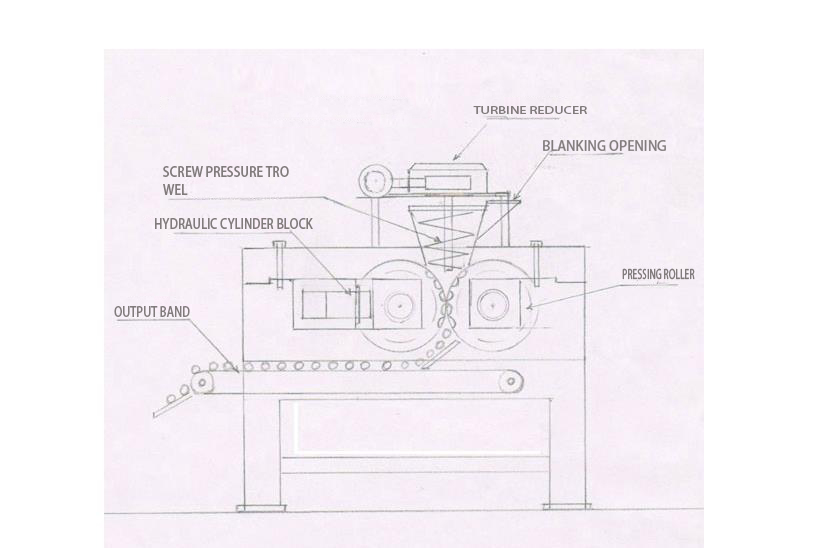

Forced feeding structure (screw feeding) and hydraulic power system

Compared with ordinary roller presses, their biggest difference in appearance is that hydraulic roller presses have forced feed structure and hydraulic power system (although some ordinary roller presses can also be equipped with this system, each hydraulic roller press has this system).

Force feeding

Briquette machine force feeding strcuture

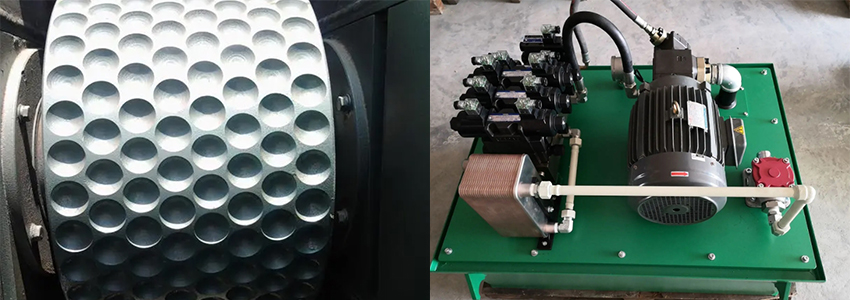

Hydraulic power system

Briquette machine hydraulic system

The hydraulic power system will provide much greater pressure than the ordinary briquetting process. Another advantage of the system is that it can prevent the drum from being damaged by blocky and hard materials. The theory is as follows:

The hydraulic pump pumps high-pressure oil into the hydraulic cylinder to make the piston move axially. The piston rod stabilizes the bearing seat, making the roller clearance smaller, which means high pressure. When there is too much material or metal between the rollers, the piston rod of the hydraulic cylinder will be overloaded, which will stop the hydraulic pump, and then the high pressure oil will return and the pressure will drop, the gap between the rollers will return to normal, and then the material will pass through the rollers.

Materials available for High Pressure Roll Briquette Machine

Quicklime, salt, refractory, ceramic powder, copper powder, chrome ore powder, lead and zinc waste, aluminum slag and various materials that can be compacted by ordinary roller compactor.

Material Requirement

Size: 80-200 mesh (0.74mm-1.78mm);

Moisture: less than 6%;

Does the High Pressure Roll Briquette Machine require adhesive?

Due to the high pressure of hydraulic pressure block system. We press the block without adhesive. But in some special applications, we can also add adhesives.

Features

1.High briquetting rate and high briquetting strength;

2.Long service life of roll surface;

3.The double-shaft reducer structure is adopted to improve the roll accuracy,

4.Adopt all-steel reduction gearbox, with good sealing performance

5.Adopt hardened gear to improve service performance and service life;

6.The preloading device adopts adjustable speed motor

7.All wear-resistant parts are welded wear-resistant alloys to improve the service performance and service life;

8.The hydraulic station is placed independently, can adjust the pressure and has the function of super pressure protection.

Application scope of High Pressure Roll Briquette Machine

light metal industries such as coal, mining, metallurgy, refractories, building materials, etc

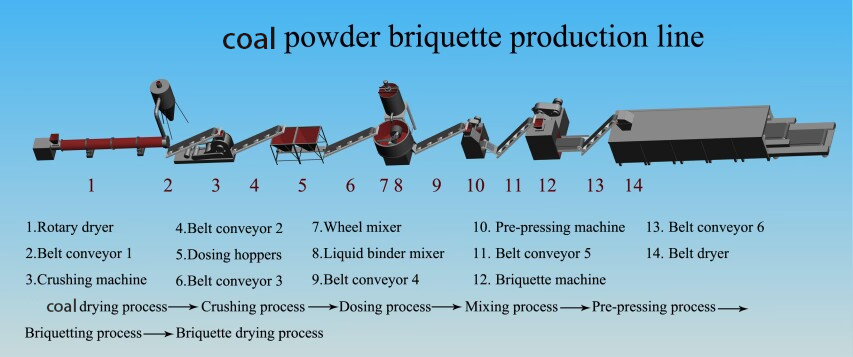

Process display of coal powder ball press plant

Process display of coal powder ball press plant

Crusher: If your material is too large, generally speaking, you must use a crusher, otherwise the working life of the drum will be shortened. In addition, obtaining materials with proper size is also a method to prepare high-quality briquette;

Silo: The silo is used to store materials for smooth feeding in the next step;

Conveyor: because the hydraulic roller adopts the spiral force feeding structure, the commonly used feeding conveyor is the screw conveyor.

Not every dry roller forming plant follows the above process. Depending on your order, the process may vary greatly. You can follow our solution center to learn more about the briquette plant, or contact us for customized design.

High Pressure Roll Briquette Machine Parameter

| Model | Capacity (t/h) | Roller diameter (mm) | Roller width (mm) | Maximum pressure (t) | Weight (t) | Size (m) | Power (kw) |

| HSYQH-450 | 8 | 450 | 250 | 400 | 6.3 | 3*2.8*2.6 | 37 |

| HSYQH-500 | 15 | 500 | 300 | 300 | 6.1 | 3*2.2*2.6 | 37-4 |

| HSYQH-650 | 18 | 650 | 300 | 300 | 10 | 3*2.5*2.6 | 45 |

| HSYQH-750 | 20-22 | 750 | 300 | 300 | 11 | 3*2.5*2.6 | 55 |

| HSYQH-850 | 25 | 1000 | 300 | 300 | 14 | 3*2.8*2.6 | 55 |

| HSYQH-290 | 3 | 290 | 200 | 30 | 1.5 | 1.8*1.35*1.85 | 7.5 |

| HSYQH-360 | 5 | 360 | 240 | 30 | 2.5 | 1.8*1.5*1.8 | 15-18.5 |

| HSYQH-400 | 6 | 400 | 240 | 30 | 2.8 | 2.1*1.5*1.9 | 15-18.5 |

| HSYQH-520 | 6-10 | 520 | 240 | 400 | 12 | 3.7*2.8*2.2 | 55 |

| HSYQH-560 | 8 | 560 | 220 | 400 | 16 | 3.7*2.8*2.2 | 45-6 |

| HSYQH-700 | 8-12 | 700 | 225 | 400 | 18 | 4*2.8*2.5 | 75-6 |

High Pressure Roll Briquette Machine price

Due to the high pressure of the High Pressure Roll Briquette Machine, it has high requirements for the material and quality of its internal parts. Therefore, the cost of High Pressure Roll Briquette Machine is much higher than that of the ordinary ball press

Tell us about your raw materials and the size and density of the finished product, and we will help you find the most suitable ball pressing machine for you