Vertical crusher

Vertical crusher is a kind of hammer crusher without grate bar and fine grinding equipment, which is widely used in sand making process. With this feature, vertical crusher can be an ideal choice for materials with large volume and large hardness before crushing. The vertical crusher is also used for crushing coal, coke powder, flint clay, limestone, cement clinker, mixture, gypsum, coal gangue, blast furnace slag, copper ore, iron ore, lead-zinc ore, serpentine, shale, dolomite, phosphate rock, granite, basalt and other materials.

Applicable raw material

Pebble, coal block, granite, basalt, iron ore, calcium carbonate, limestone, quartz, coal gangue, construction waste, etc

It is suitable for raw materials & revert crushing, especially for high moisture content materials, strong adaptability, not easy blocking, smoothly feed.

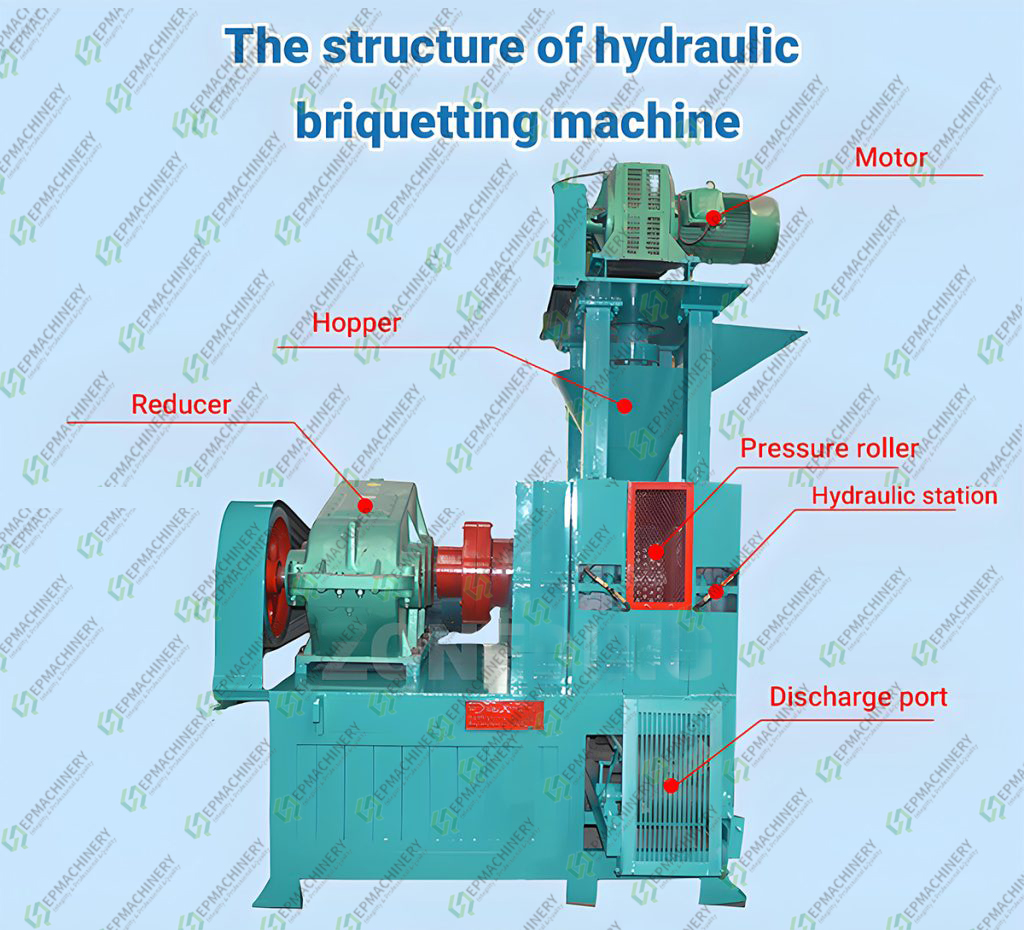

Structure

1.The crushing ratio is large, which can be adjusted arbitrarily.

2.No screen, no block.

3.Using elastic adjusting mechanism, the hard impurities can be discharged automatically without causing damage to the equipment.

4.Horizontal bearing, long service life, which can break materials with high temperature (such as cement clinker).

5.The structure of the rotor of the machine is unique. When working, the rotor hardly wears.

6.The rear chamber is equipped with a screw or hydraulic opening mechanism, which can easily replace the fragile parts without opening the main equipment.

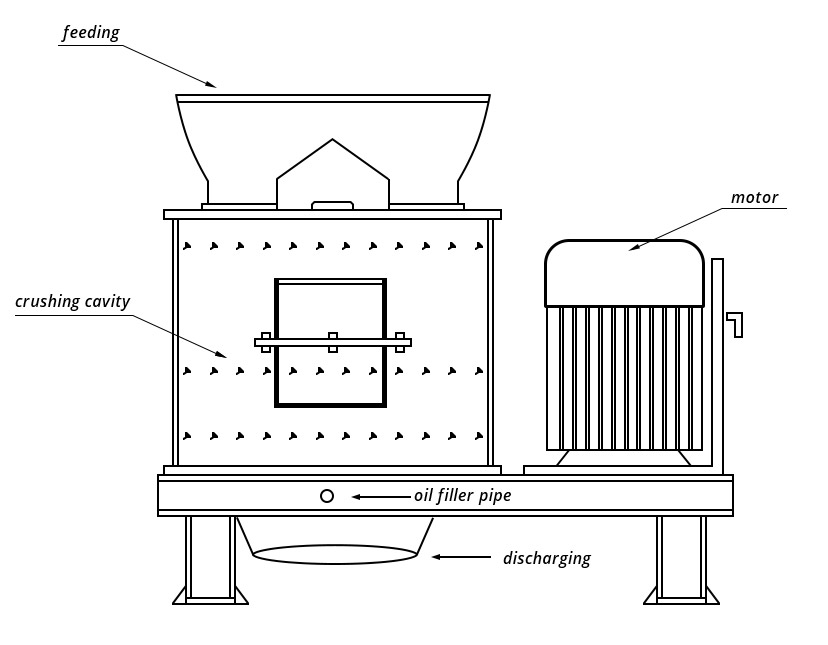

Working Principle

Vertical crusher Working Principle

Materials are vertically dropped into the high-speed rotating impeller from the upper part of the composite crusher. Under the action of high-speed centrifugal force, the materials which are distributed around the impeller in umbrella form with the other part produces high-speed impact and crushing. After the material collides with each other, it will form eddy current between the impeller and the casing to collide and crush with each other for many times. The material will be discharged directly from the bottom part to form closed-circuit multiple cycles, and the sieving part will control the required finished product size.

Feature

.Simple and reasonable structure, low operating costs

.Use the stone-stone principle, low cost on wear-parts.

.High crushing rate, energy saving.

.No screen, low requirement on moisture, raw material moisture acceptable up to 8%.

.Low working noise below 75 dB (db level), less dust.

.Suitable for crushing mid-hard to hard materials.

.Final product with cubic shape, high bulk density, small iron pollution for raw material.

.Easy maintenance.

Applicable production line

Charcoal briquette production line

Parameter

| Model | Barrel Diameter (mm) | Capacity (m³/h) | Power (kw) |

| YKVC650 | 650 | 1-10 | 11-15 |

| YKVC800 | 800 | 3-15 | 15-22 |

| YKVC1000 | 1000 | 5-30 | 22-37 |